PRODUCTS & CAPABILITIES

Download our full capabilities PDF

Custom Plastic Molding Capabilities

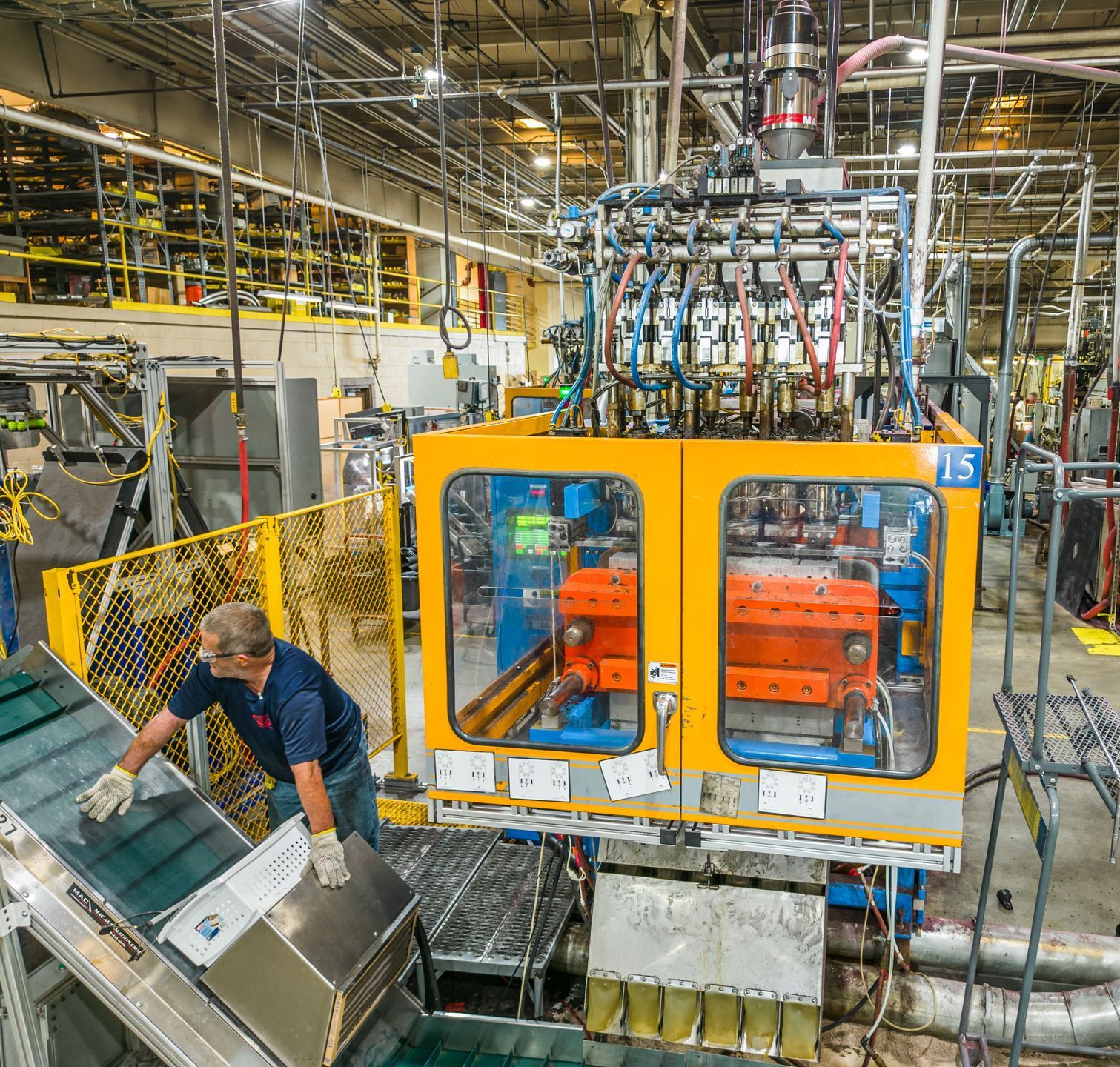

OMICO is a blow molding company where we pride ourselves on our flexibility and on-time delivery rates. In our manufacturing procedures we are environmentally conscious, emissions free and always recycle product waste materials.

As more companies move away from metal and toward a more durable plastic, we are prepared for an increase in the usage of plastics and, therefore, production.

Our staff and machinery are able to manufacture a range of products varying in size from an inch to six feet. These products are used in various applications: automotive boots (protective covers), refrigerator drain tubes, air ducts, water reservoirs, parts for dishwashers and vacuum cleaners, bin doors and food service panels, carafes, serving trays and insulated plates. Over our 50 years, we’ve received awards by well-known companies such as Whirlpool, General Electric Appliances, General Motors and Hoshizaki.

An Overview of the Blow Molding Process

Blow molding is a manufacturing process that employs two-piece molds to create hollow parts and products made from plastic or glass. Industry professionals may use different variations of the process, such as extrusion blow molding, injection blow molding, or stretch blow molding, depending on the part and production requirements.

The Blow Molding Process at OMICO

At OMICO, we offer full-service blow molding solutions to help customers at every stage of the production process. Equipped with over five decades of industry experience and 26 blow molding machines, we can accommodate a wide range of project specifications, including:

- Shot capacities of 0.66 to 25 lbs.

- Product sizes ranging from 1 in. to 6 ft.

- Multi-component assemblies requiring plastic welding and press fitting

- Foam filling for insulated products

In addition to our blow molding capabilities, we offer custom mold design, new product development, existing product redesign, finishing, inspection, assembly, and packaging and shipping services.

A typical blow molding project proceeds as follows:

- Designing the custom product mold

- Blending and plasticizing the raw material

- Extruding the plastic as a parison (i.e., a sleeve of material)

- Enclosing the parison inside of the mold form

- Introducing compressed air to force the plastic to adhere to the mold design

- Removing the hollow form from the machine

- Trimming, inspecting, and assembling the form to customer specifications

- Packing and shipping the finished blow molded component for delivery to the customer

- Shredding and reprocessing waste material

For additional information about our blow molding capabilities, get in touch with our team!

OMICO IS A WORLD-CLASS SUPPLIER OF CUSTOM PLASTIC COMPONENTS

What to expect from Omico Plastics:

By partnering with us for their blow molding needs, customers benefit from our:

- Superior service: Our engineers work with customers to create custom molds for their parts and products while our customer service team dedicates themselves to meeting production schedules.

- Excellent product and process quality. We carefully track and document all materials and products across all manufacturing stages. Additionally, we use a Statistical Process Control process to ensure process consistency and product quality. We are proud to make quality product 99.999% of the time and have maintained this over the years

- On-time delivery. We boast an on-time delivery rate of 99.9%.

- Efficient production in time, equipment and materials.

- An engineering team to work with you as they create a mold specific to your designs.

- Technically knowledgeable and experienced customer service personnel dedicated to meeting your product schedule needs.

- Use of a Statistical Process Control Program allowing us to eliminate process variation and constantly improve product quality.

- Materials and products to be tracked and documented through every stage of the manufacturing process.

Our Equipment List

| EQUIPMENT | ||||

|---|---|---|---|---|

| Manufacturer | Model | # Heads | Shot Capacity | Extruder Size |

| Uniloy-Milicron | T80001 | 1 | 25 lb | 90 mm |

| Davis Standard | SE415 | 2 | 2 @ 15 lb | 115 mm |

| Davis Standard | SE305D | 2 | 2 @ 5 lb | 90 mm |

| Hycon | MCH-5-5 | 1 | 5 lb | 90 mm |

| Cullom | CVF V-4-42 | 1 | 380 lb/hr | 80 mm |

| Davis Standard | FHB-106-2 | 1 | 350 lb/hr | 80 mm |

| Improved | B-37 R250 | 1 or 2 | 1590 g | 108 mm |

| Improved | B-30 R180 | 1 or 2 | 1135 g | 95 mm |

| Improved | B-30 R180 | 1 or 2 | 1135 g | 95 mm |

| Rocheleau | RS-25 | 6 | 908 g | 70 mm |

| Rocheleau | RS-25 | 5 | 908 g | 70 mm |

| Rocheleau | RS-25 | 6 | 908 g | 70 mm |

| Rocheleau | RS-25 | 4 | 908 g | 70 mm |

| Rocheleau | RS-25 | 4 | 908 g | 70 mm |

| Hycon | MCH-1-50 | 4 | 681 g | 58 mm |

| Hycon | MCH-1-50 | 4 | 681 g | 58 mm |

| Hycon | MCH-1-50 | 4 | 681 g | 58 mm |

| Hycon | MCH-1-50 | 4 | 681 g | 58 mm |

| Rocheleau | SPB-2 | 4 | 570 g | 50 mm |

| Rocheleau | SPB-2 | 2 | 570 g | 50 mm |

| Rocheleau | SPB-2 | 3 | 425 g | 45 mm |

| Rocheleau | SPB-3 | 2 | 380 g | 57 mm |

| Rocheleau | R-4 | 1 | 300 g | 38 mm |

| Rocheleau | R-4 | 3 | 300 g | 38 mm |

| Rocheleau | R-4 | 1 | 300 g | 38 mm |

| Rocheleau | R-4 | 1 | 300 g | 38 mm |

| Rocheleau | R-4 | 1 | 300 g | 38 mm |